All About Failure Mode and Effects Analysis (FMEA)

Developing your next product? Conducting a FMEA is an efficient, comprehensive approach to proactive risk assessment

If you’re a product manager, you may already know that at least 75% of products fail. Sometimes, this failure is due to poor understanding of the market or customer requirements. Other times, it’s due to poor internal processes or poor product development approaches.

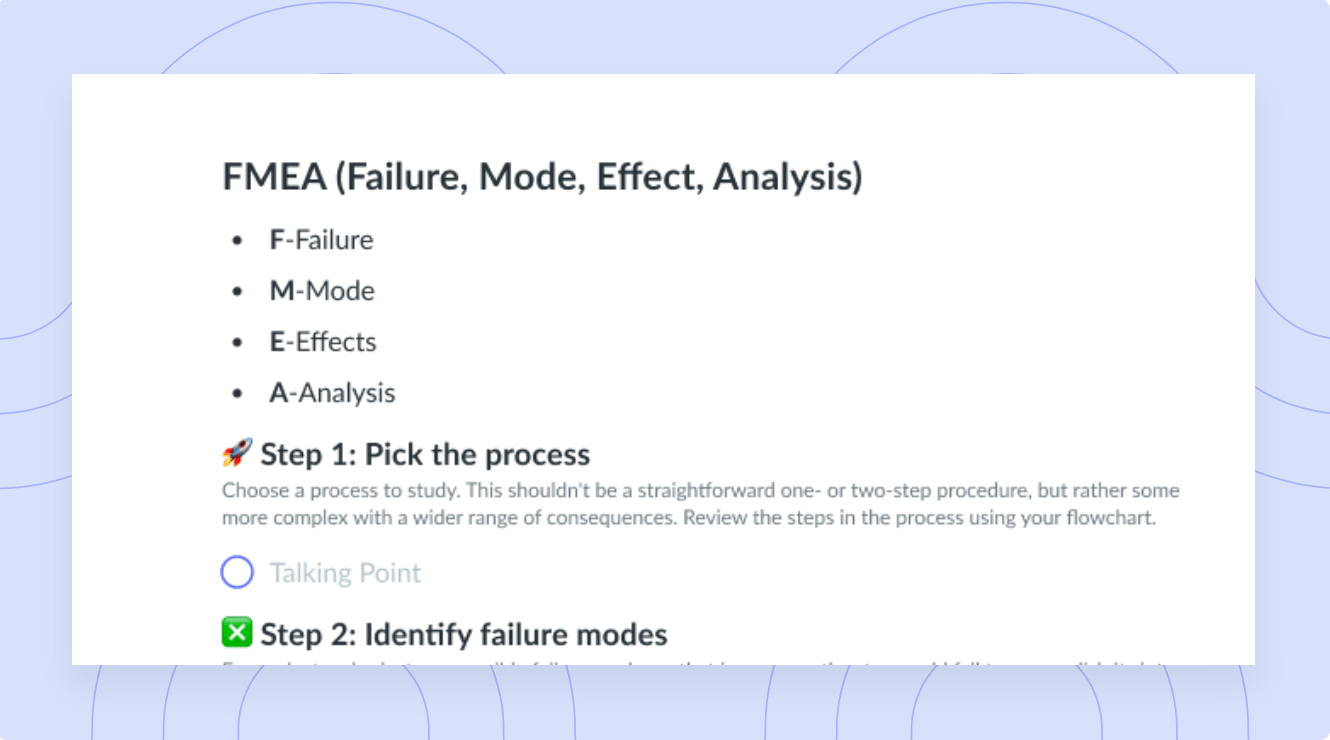

Failure Modes and Effects Analysis (FMEA) is a structured process for identifying risks in new products and can help identify and mitigate potential reasons for product failure before launch. This technique is also known as the failure modes effects and criticality analysis (FMECA).

We’re here to introduce you to what FMEA is, and the 10 simple steps you can take today to integrate FMEA into your product development life cycle.

- What is Failure Modes and Effects Analysis (FMEA)?

- When to use FMEA

- How to conduct an FMEA

- Free FMEA template

What is Failure Modes and Effects Analysis (FMEA)?

FMEA is a powerful, proactive approach to conducting risk assessment. It is often used in high-risk industries such as aerospace, medicine, automotives, and semiconductors manufacturing where defects can be more difficult to assess or where defects may have higher impacts if they occur.

FMEA analyzes the requirements or features of the product and attempts to identify all possible issues that could negatively impact the user’s experience with the end product. Effectively, it helps identify which features of the product pose the greatest risk, and thereby directs product developers towards actions that could improve the product’s performance.

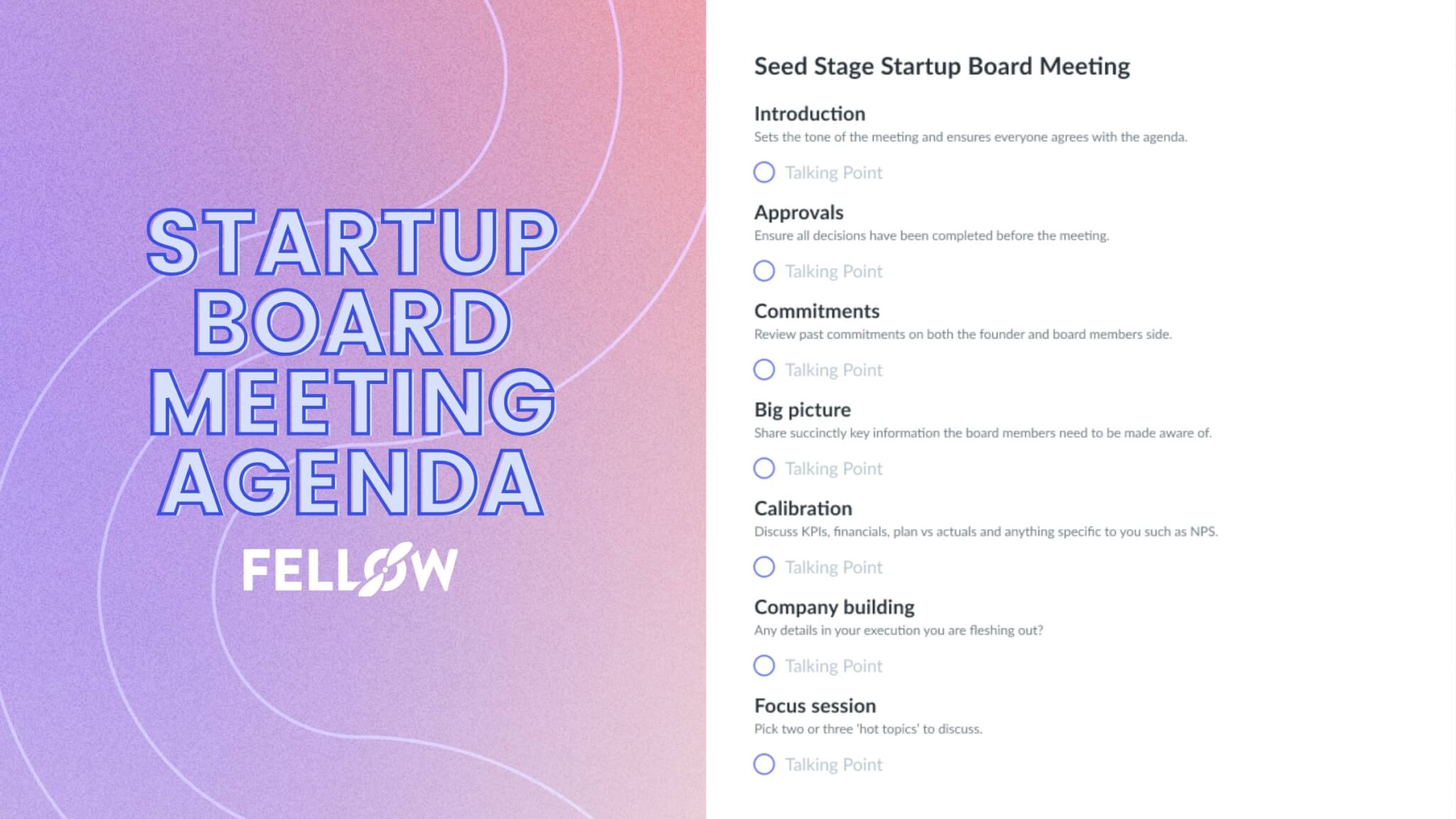

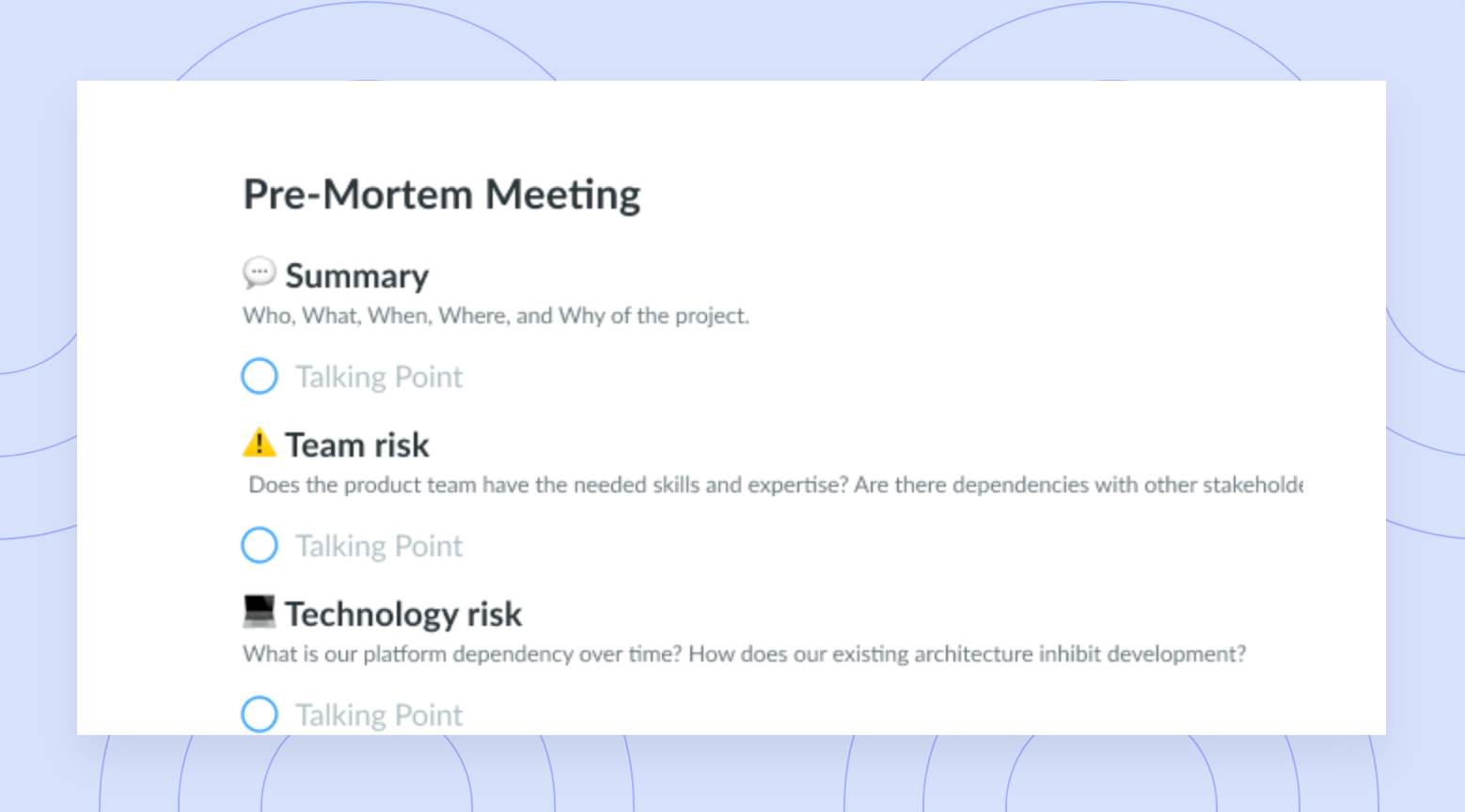

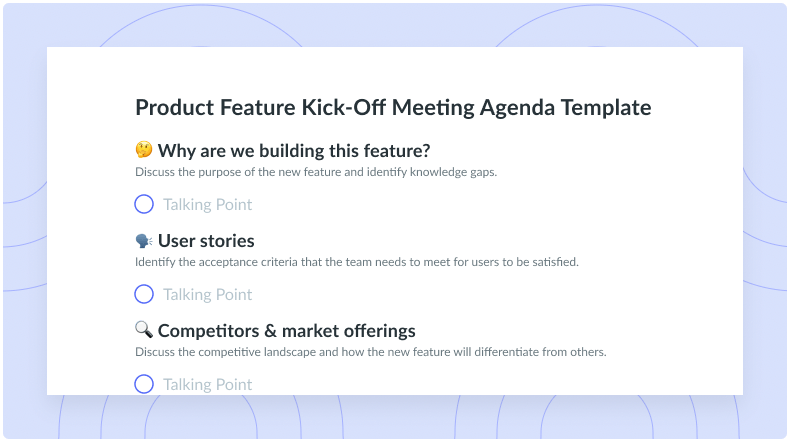

Great meetings are just the start

Level up your meeting habits to boost engagement and productivity with a collaborative meeting agenda. Try a tool like Fellow!

When to use FMEA

There are four different types of FMEA that can be applied to different aspects of the product development lifecycle.

- Design FMEA. This type of analysis looks for defects in the product itself. For example, the defect may be a risk with a product function, material, packaging, or something else that is directly related to the actual product.

- Process FMEA. With process FMEA, the goal is to identify a defect or risk in the processes that help develop the product. For example, a risk may be found in the development, handling, or manufacturing processes as the product is being built.

- Service FMEA. Service risks are those that make the product usable or increase the usability of the product after delivery to the customer. This may include risks in installation support, repair or maintenance services, or customer service concerns.

- Schedule FMEA. This type of FMEA looks at the risks that may affect the product shipping out or delivering on time. Essentially, it considers any risks that could delay the product reaching the customer. As such, it can be affected by the other three types of FMEA.

The Bathtub Curve is an important model that aligns with FMEA and identifies how failure to conduct proper FMEA can shorten a product’s lifecycle. The model highlights three major ways that products fail, and how lack of FMEA ties to this failure.

Without a process FMEA, poor manufacturing and quality control issues can cause a product to fail very early in its lifecycle, causing what’s called product infant mortality. A lack of design FMEA can lead the product to suffer usability issues or fall short on feature requirements, therefore shortening the useful life of the product. The third biggest risk the Bathtub Curve models is in the late stages of a product’s lifecycle, when inadequate service FMEA can lead the product to fail due to insufficient maintenance support or poor customer service. This, in turn, accelerates the speed at which the product is worn out in the market.

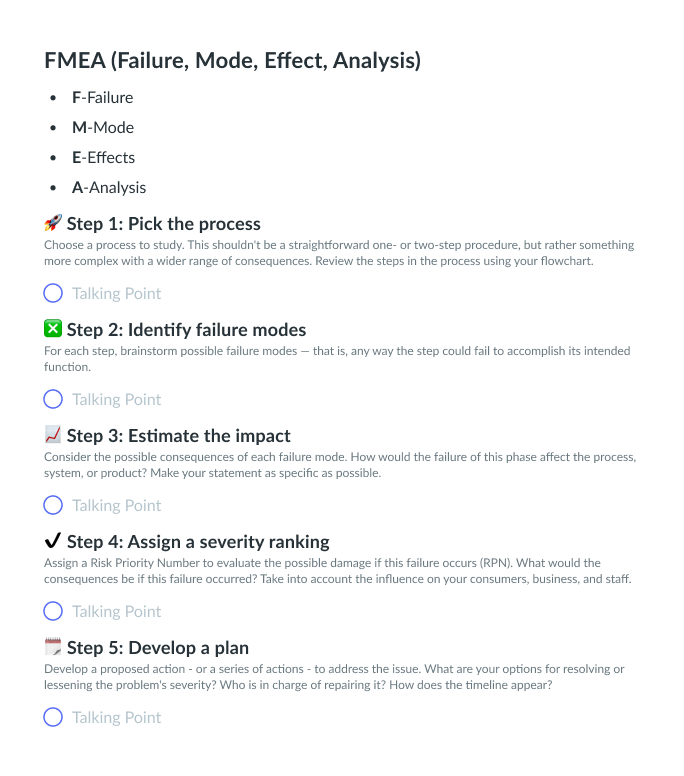

How to conduct an FMEA

- Organize a cross-functional team

- Choose an area to analyze

- Identify failure modes

- Consider possible consequences

- Determine occurrence rankings

- Determine severity rankings

- Determine detection rankings

- Calculate your risk priority number (RPN)

- Develop an action plan

- Track progress and results

1Organize a cross-functional team

Bringing together a cross-functional team will provide important insights from multiple departments or knowledge areas within your organization. While engineering departments can bring technical expertise, marketing or sales departments can bring insights related to consumer requirements and use cases. Additionally, operations teams can provide input on schedule planning risks.

2Choose an area to analyze

From the four types of FMEA described above, choose one at a time to analyze. Focusing on only one type of FMEA at a time allows your team to immerse in deeper knowledge on each individual type of FMEA. This will allow you to define greater insights.

At this stage, it’s essential to ensure that your analysis area is well aligned with the knowledge and expertise of your cross-functional team.

3Identify failure modes

Now, you dive into creating your FMEA.

Start off by having everyone on your team list off any possible failure modes (possible risks or defects). These can be of any size and any risk level. As long as a failure mode is even remotely possible, it should be included on this list.

You can even try implementing a new brainstorming technique to keep the ideas flowing.

4Consider possible consequences

The purpose of conducting an FMEA is judging the impact of possible risks so product developers can implement appropriate solutions if need be. Therefore, it’s important to list all possible consequences. This includes any risk, of any size, at any probability of occurring. In later steps, you’ll be able to break this list down into more detail, but for now it’s important just to understand what the product failures really look like for the customer (or for your organization).

5Determine occurrence rankings

Here is where you begin breaking down each failure mode into further detail.

In this step, rank each issue based on the frequency of its occurrence. Your team should create a range of frequency of occurrence on a 1-10 scale that is relevant to your product or process. For example:

- 1 = Likely to occur once every 7+ years

- 10 = Likely to occur multiple times per day

For the most accurate analysis, use any available data from user testing, customer feedback, or quality assurance testing to identify the frequency at which the issue is likely to occur.

6Determine severity rankings

Now, for each issue you need to consider the severity of each risk if it were to occur. You can rank these impacts on a scale from 1-10 as well, with 1 being the least severe impact and 10 being the most severe. Again, this range needs to be tailored to your product or process. For example:

- 1 = No effect

- 10 = Hazardous, would definitely result in death or critical injuries

7Determine detection rankings

With your severity and occurrence rankings identified, you now need to determine how likely it is the issue will be detected before it occurs. For example, an issue tucked deep inside a component may be more difficult to detect, and therefore is more difficult to prevent or mitigate. As a result, the issue may pose a greater risk (depending on its severity and frequency of occurrence). Again, your team should create a scale from 1-10 that is relevant to your product or process. Easily detectable issues would have lower scores and issues that are difficult to detect in advance would have higher scores. For example:

- 1 = Easy to detect, in plain sight

- 10 = Almost impossible to detect before occurrence

8Calculate your risk priority number (RPN)

Your Risk Priority Number (RPN) score is a calculation of Occurrence x Severity x Detection rankings. The result from your calculation will provide each issue with a specific risk number between 1 (no risk) and 1,000 (high risk which is impossible to detect and has the most significant impacts).

Typically, issues with higher RPN scores are mitigated first. Some organizations may choose to allow certain issues to go unmitigated, especially if the RPN score is low, the severity is mild, or the organization does not have the capabilities to successfully mitigate or even partially mitigate the issue.

9Develop an action plan

Use your RPN results to create an action plan. An efficient plan will identify all actions that need to be completed, the order of priority, all due dates, and the roles assigned to the people responsible for completing the tasks at hand. The plan may also include resources and information that can support the completion of the tasks assigned.

10Track progress and results

Each team will have unique key performance indicators (KPIs) to track the success of the FMEA. For example, some KPIs may include:

- Time completed to mitigate issues

- Percentage of risk decreased

- Number of issues that decreased scores

- Number of issues that have less than X score

Free FMEA template

Parting advice

Conducting an FMEA is an efficient, quick way to identify the risks and consequences of a product before launch. With the appropriate knowledge and expertise from your cross-team collaboration, you can create a deeply insightful FMEA and a clear, action-oriented plan of attack for mitigating risk in your next product development life cycle.