Kaizen Principle: How to Improve Performance and Empower Your Team

The Kaizen principle can help fuel lasting long-term improvements with frequent smaller changes. Empower your team with this how-to guide.

Better work rarely happens overnight, and the Kaizen principle leans into the positive side of this potentially discouraging idea. Kaizen, a popular project management theory developed in Japan in the 1950s, emphasizes how tiny actions every day lead to stronger long-term outcomes. Its main point is that any problems you solve today result in far fewer problems in the days, weeks, months, and years to come. Plus, it’s easy to start using the Kaizen principle in your workplace—learn more below.

- What is Kaizen?

- The benefits of the Kaizen principle

- The five elements of Kaizen

- The five-step Kaizen process

- Examples of organizations applying the Kaizen method

- Continuously improving with Fellow

What is Kaizen?

Kaizen is a Japanese word that means “change for the better,” and many also translate it as “continuous improvement.” In leadership and management, the Kaizen principle is the ongoing, gradual implementation of small changes that make a big difference over time. All team members, whether entry-level or C-suite, are involved in these changes, resulting in more efficient, fulfilling work environments and tasks.

Kaizen first emerged when the Toyota Motor Corporation’s methods for internal changes led to greater output and higher product quality. These changes evolved into the Toyota Production System, and in the 1980s, management consultant Masaaki Imai attributed this system to a process of continued improvement. His 1986 book detailing the system was called Kaizen: The Key to Japan’s Competitive Success, and the name stuck.

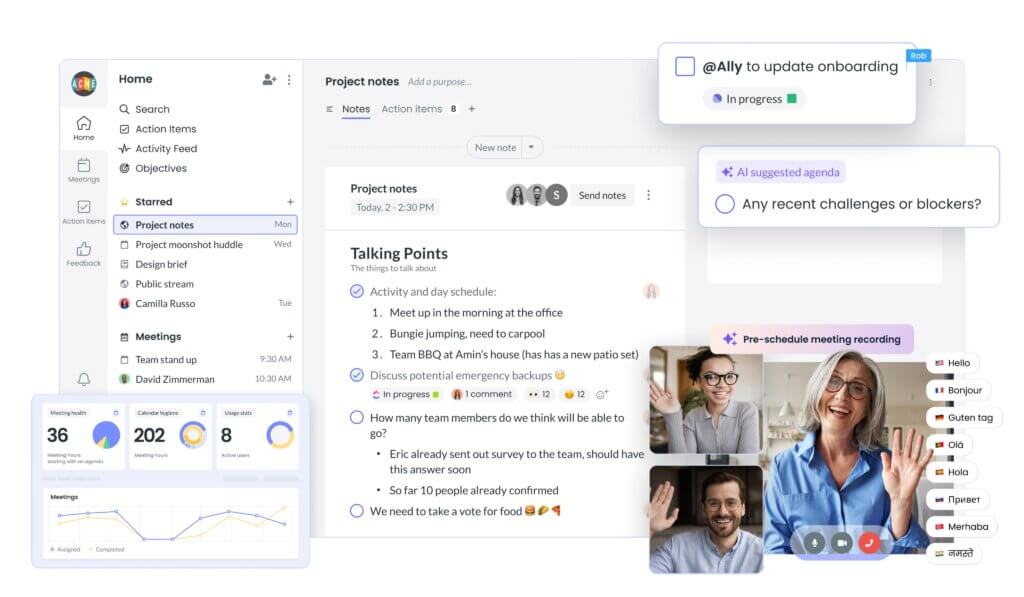

Your meeting problem, solved.

Fellow is the only all-in-one meeting management software for remote and hybrid teams. Have fewer, more effective meetings and 1-on-1s with AI, behavior-driving features, and seamless integrations.

The benefits of the Kaizen principle

When Kaizen continuous improvement becomes a part of your management style, the following great outcomes usually follow.

1Better teamwork

Adopting the Kaizen philosophy means getting everyone in your organization to work toward the shared goal of improvement. This extensive collaboration leads to the kind of trust that all but guarantees better teamwork. Everyone around you will be working together at their best, so you’ll improve employee performance and streamline communication across your organization.

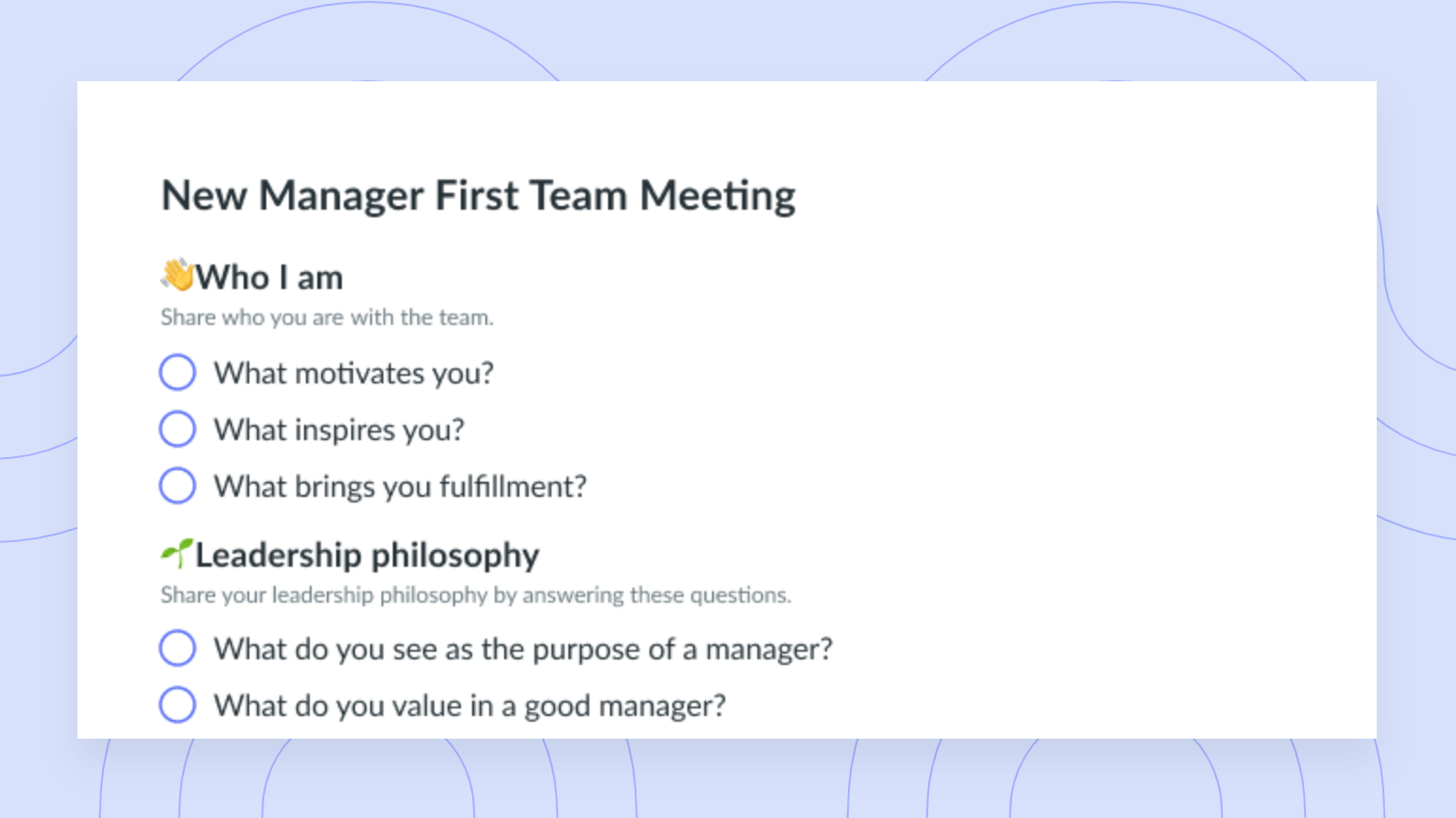

2More developed managers

When you dive into Kaizen, you’ll need to appoint a Kaizen leader. If you choose one of your managers for this role, chances are that as this person spends time making things better, manager improvement will result. If you choose someone who isn’t a manager, you’ll allow them to develop their management skills. Either way, you’ll have better managers in your court, making for better team performance across the board.

3Higher efficiency

Improvement means cutting waste. When you pull that off, you achieve the same results using fewer resources. That’s the essence of efficiency—especially if the waste you’re cutting is time. Faster teams achieving the same results are a hallmark of Kaizen success.

The five elements of Kaizen

Depending on whom you ask, Kaizen’s five elements might look totally different. In fact, you could encounter as many as four different sets of elements in your research. Confusing, right? Not as much as you might think—the below set of five Kaizen elements is the most trustworthy.

1Know your customer

At the end of the day, you do your work for your clients or customers. This means that improving work performance and continuing to grow starts with knowing how to best serve your customers. It’s also why the first element of Kaizen is understanding your customer’s interests and using this information to enhance their experience. In doing so, you build unbeatable value for the customer.

2Let it flow

In a perfect workplace, there would be no waste in any of your processes. In reality, it doesn’t quite work like that—but the “let it flow” element of Kaizen encourages you to get as close as possible. It reminds everyone on your team to continuously look for and eliminate inefficiencies while building value for the customer.

3Go to Gemba

The word “Gemba” means “the real place,” and that’s the whole point of this Kaizen pillar. Your goal is to go where something is actually happening, but it’s not like you’re leaving the office to head somewhere special. Instead, you’re figuring out where, within the levels of your organization, all the action is happening. Focus on improvements there to minimize waste and drive customer value.

4Empower people

According to this element of the Kaizen principle, all teams within your organization should have the same goals. This isn’t to say that your marketing and HR teams should work on the same tasks—of course not! Instead, you should organize each team and lay out their goals in similar ways to cut waste and maximize value. Empower your teams with whatever tools and systems they need to pull off your goals and encourage more ownership.

5Be transparent

Share tangible, visible performance benchmarks and improvements with your team to achieve transparency within the Kaizen model. Use your data to power and explain these benchmarks and improvements. You’ll leave your team with a clear understanding of how to improve—and that’s exactly the goal.

The five-step Kaizen process

It’s one thing to know the five elements of Kaizen; it’s another thing entirely to know how to use the Kaizen philosophy. Fret not—here’s how to do it.

- Find a problem’s root cause

- Come up with a solution

- Implement your solution now and in the long run

- Look at the data (again)

- Keep going

1Find a problem’s root cause

Once you’ve identified a workplace process in need of improvement, you’ll need data to quantify and qualify the problem. What productivity levels are you reaching, and how do they compare to your targets? What do customers say about your product, and what do you want them to say instead? These are just two examples of data you can easily obtain and review to define your problem’s root cause. If you’re having trouble identifying one, you could run a problem-solving meeting to brainstorm with your team.

2Come up with a solution

A major tenet of Kaizen is empowering your whole team, and finding solutions to your problems’ root causes is a great way to engage everyone. Definitely go to Gemba—where work happens—to get your team members’ on-the-ground insights on potential improvements. This way, you get creative, employee-generated solutions that build lots of value at minimal cost.

3Implement your solution now and in the long run

Empowering people also means that when you show them a new path forward, you also take your own actions to help them get moving. That’s what this step in the Kaizen process is all about. Immediately put work into the short-term solution you’ve come up with, and contribute every day to your team’s longer-term goals. Improvement is likely both today and long after.

4Look at the data (again)

Pull up your data to see how effective your Kaizen approach has been to date. Look at how the changes you’ve put into motion have impacted everyone’s performance, then share the news with your team. Do this regularly, and you’ll show that you care about improving your organization and its processes. Chances are that if you’re interested, your team will be too.

5Keep going

In continuous improvement, it’s important to, well… continue improving. There’s always something you can do better, and Kaizen involves regularly finding and acting on these areas. Frequently ask your team for feedback and review your current processes to find potential goals. After all, if your goal is continually doing things better, that really has no end date.

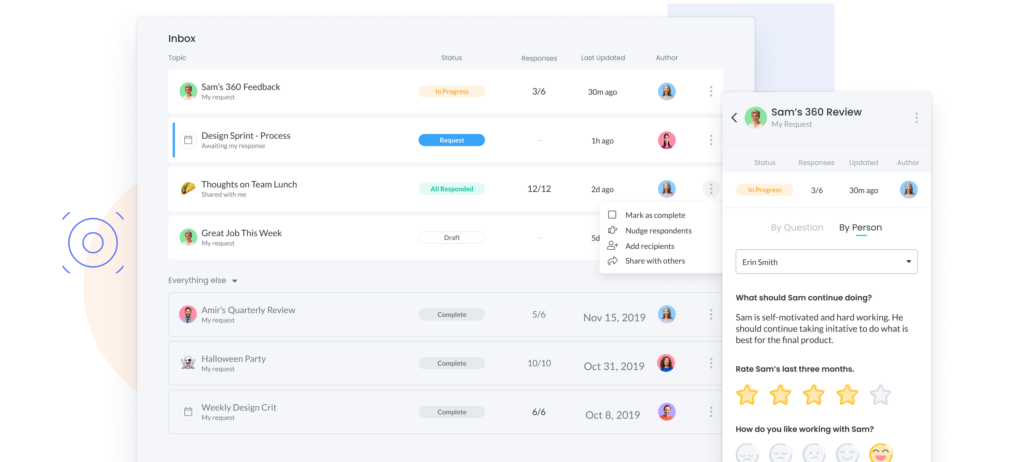

Promote a culture of asking for feedback

A healthy and strong culture starts with feedback. With Fellow, you can incorporate feedback into your team’s day-to-day experience and track progress over time.

Examples of organizations applying the Kaizen method

Some of the biggest organizations in the world find success with the Kaizen model. These companies include the below Kaizen examples.

1Toyota

Toyota is the very organization from which Kaizen emerged—it’s a company well-known for making tiny but regular changes to its processes. You might think Toyota uses this philosophy only on the manufacturing line, but it also applies this notion to employee management. With stronger product processes and happier employees, no wonder Toyota has achieved so much success.

2Ford

Whereas Toyota originated Kaizen in the 1950s, fellow car company Ford didn’t adopt this philosophy until 2006. That year, then-CEO Alan Mulally and Mark Fields, another former Ford CEO, used Kaizen for process efficiency. Over several years, the two led Ford’s employees in achieving the same process results in less time, thus cutting waste and driving value.

3Nestle

When you first hear the word “waste,” you might think of food, and in that industry, Kaizen is highly popular. In particular, Nestle has implemented Kaizen and cut back significantly on the time and raw materials its processes require. The company has also figured out how to best use its physical space and technology to maximize efficiency.

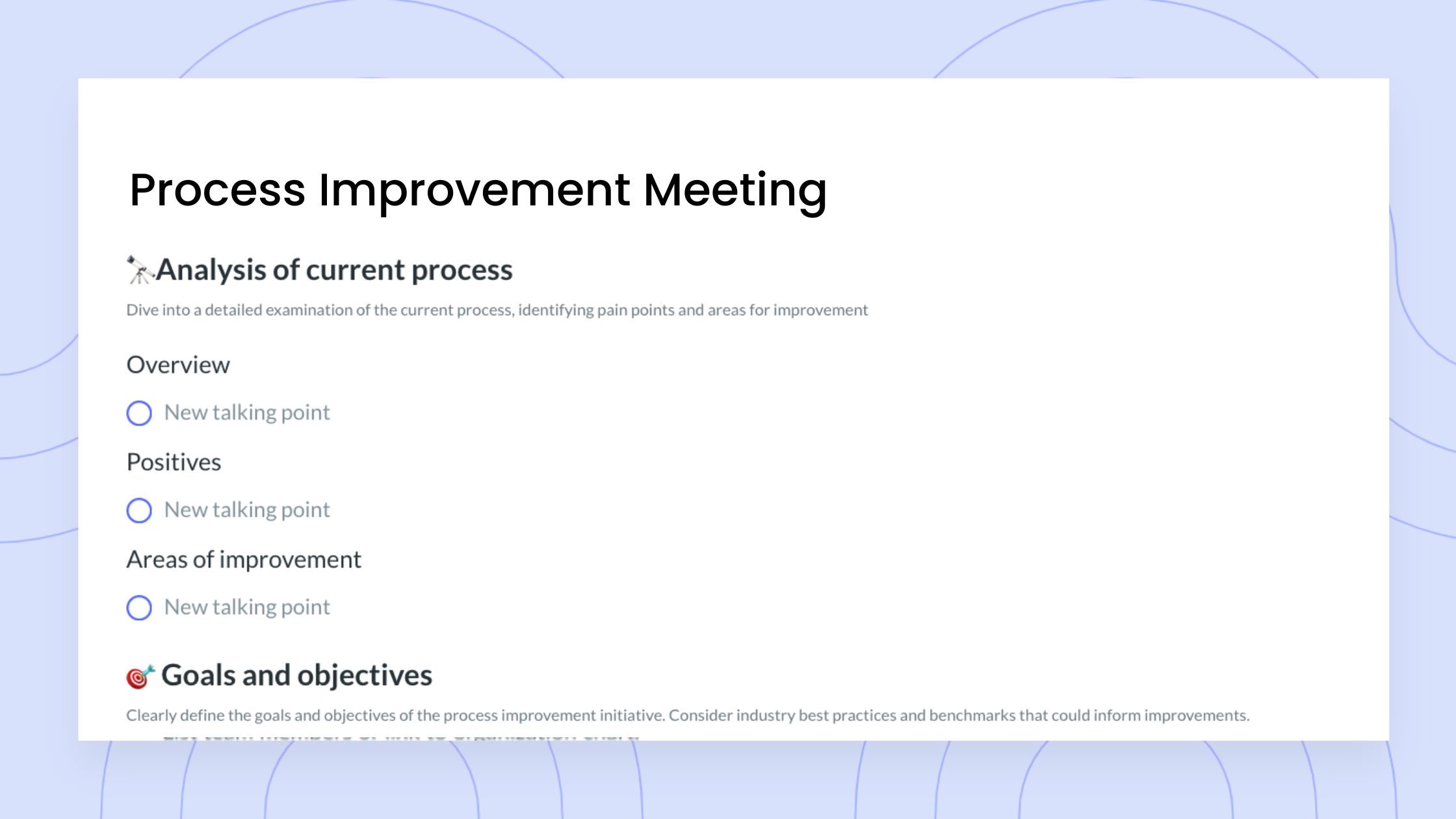

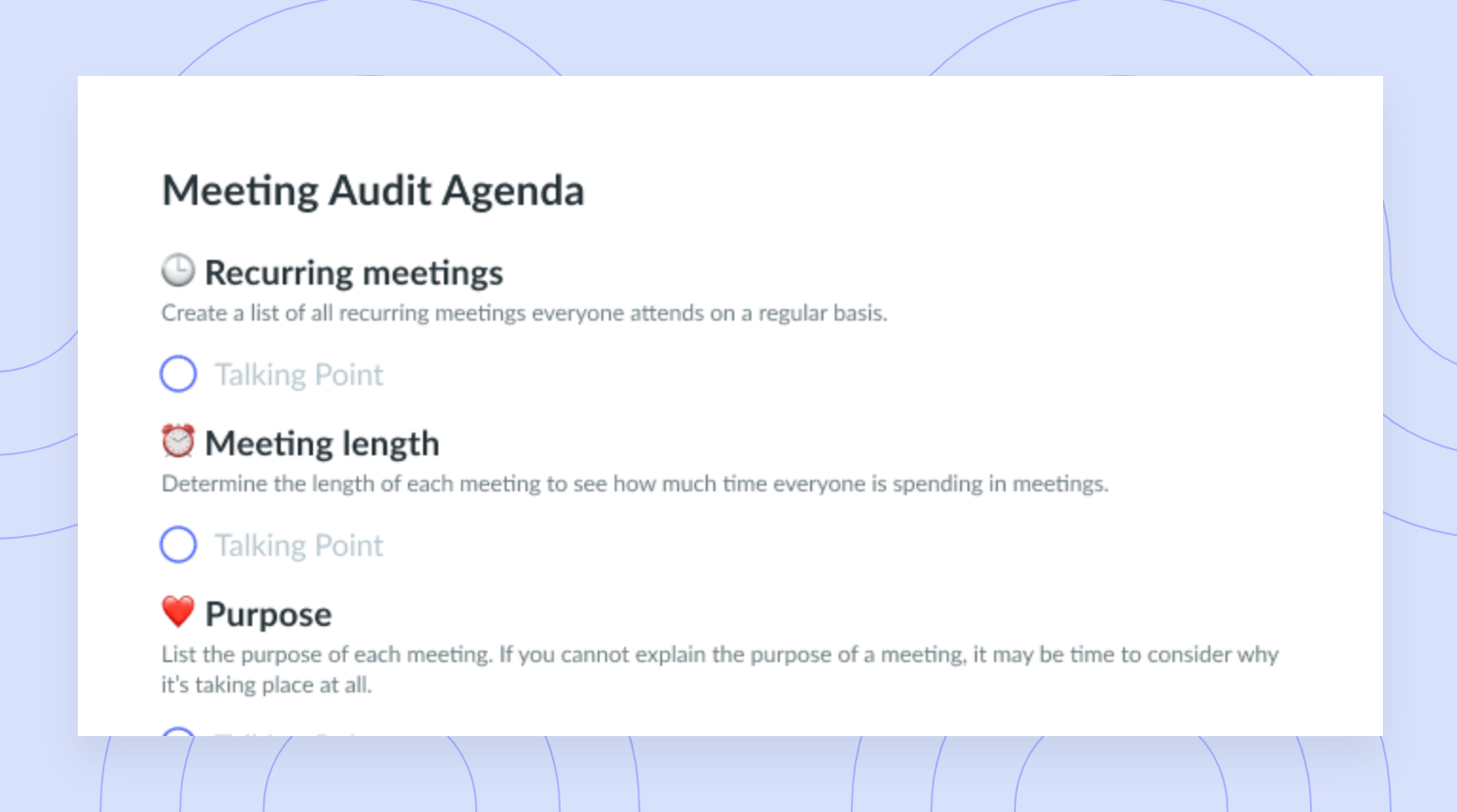

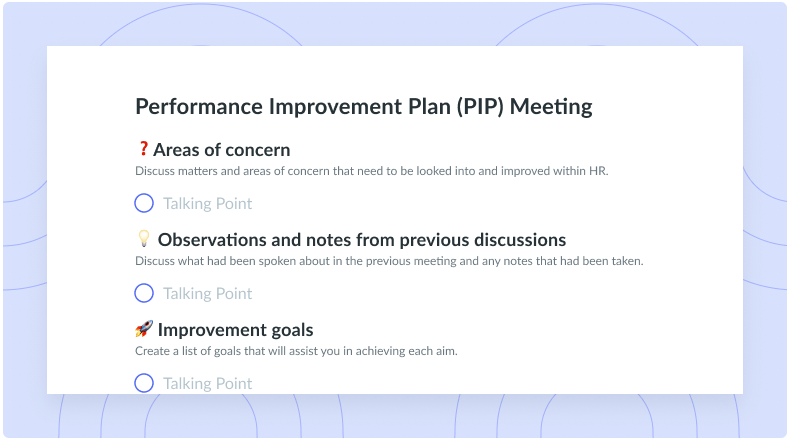

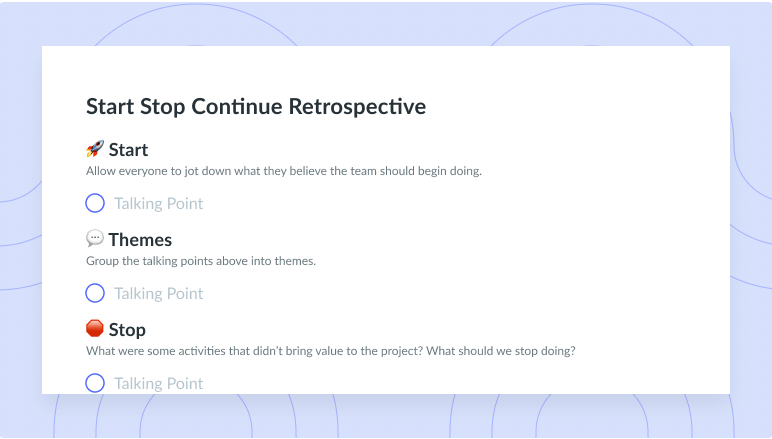

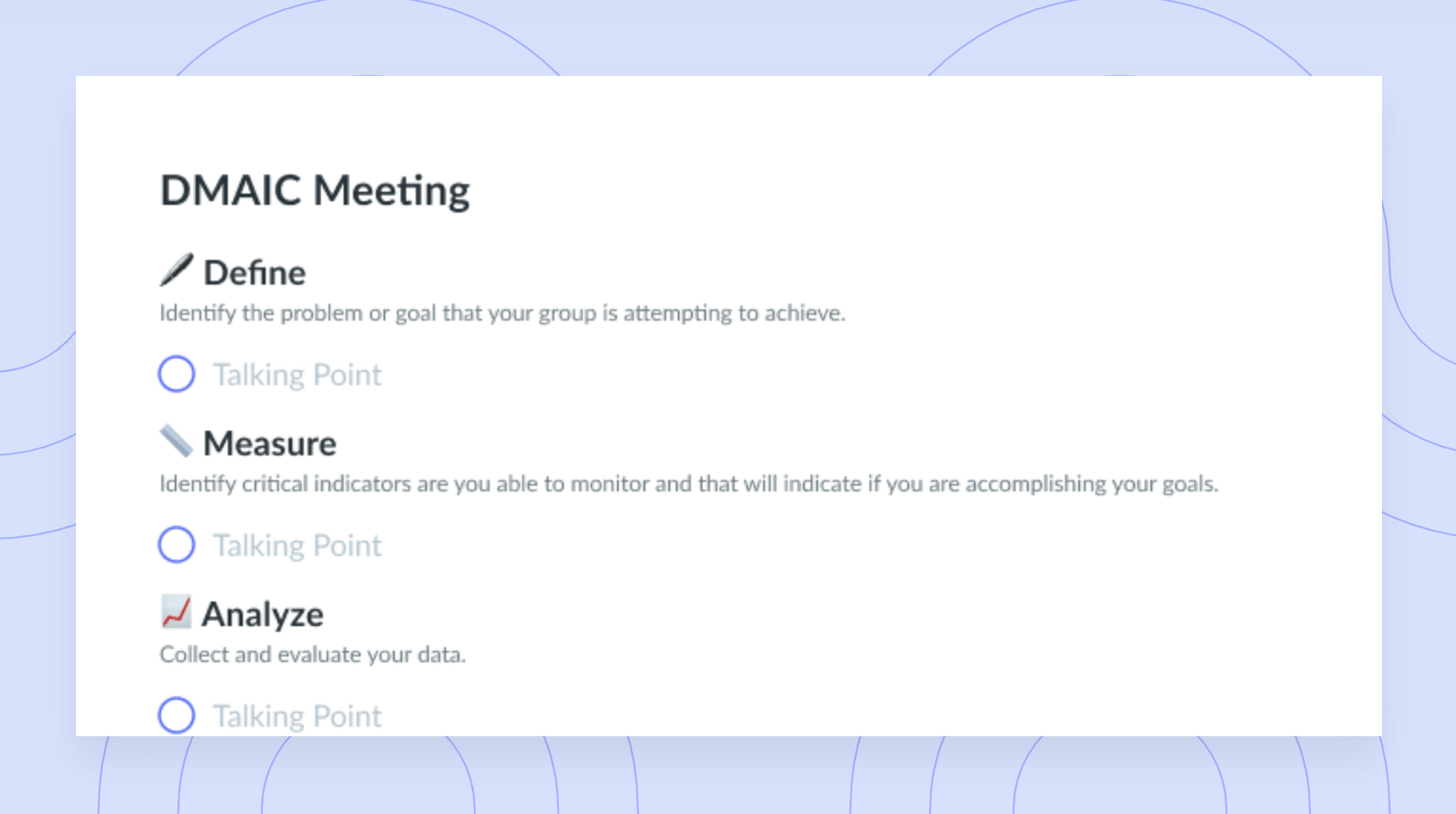

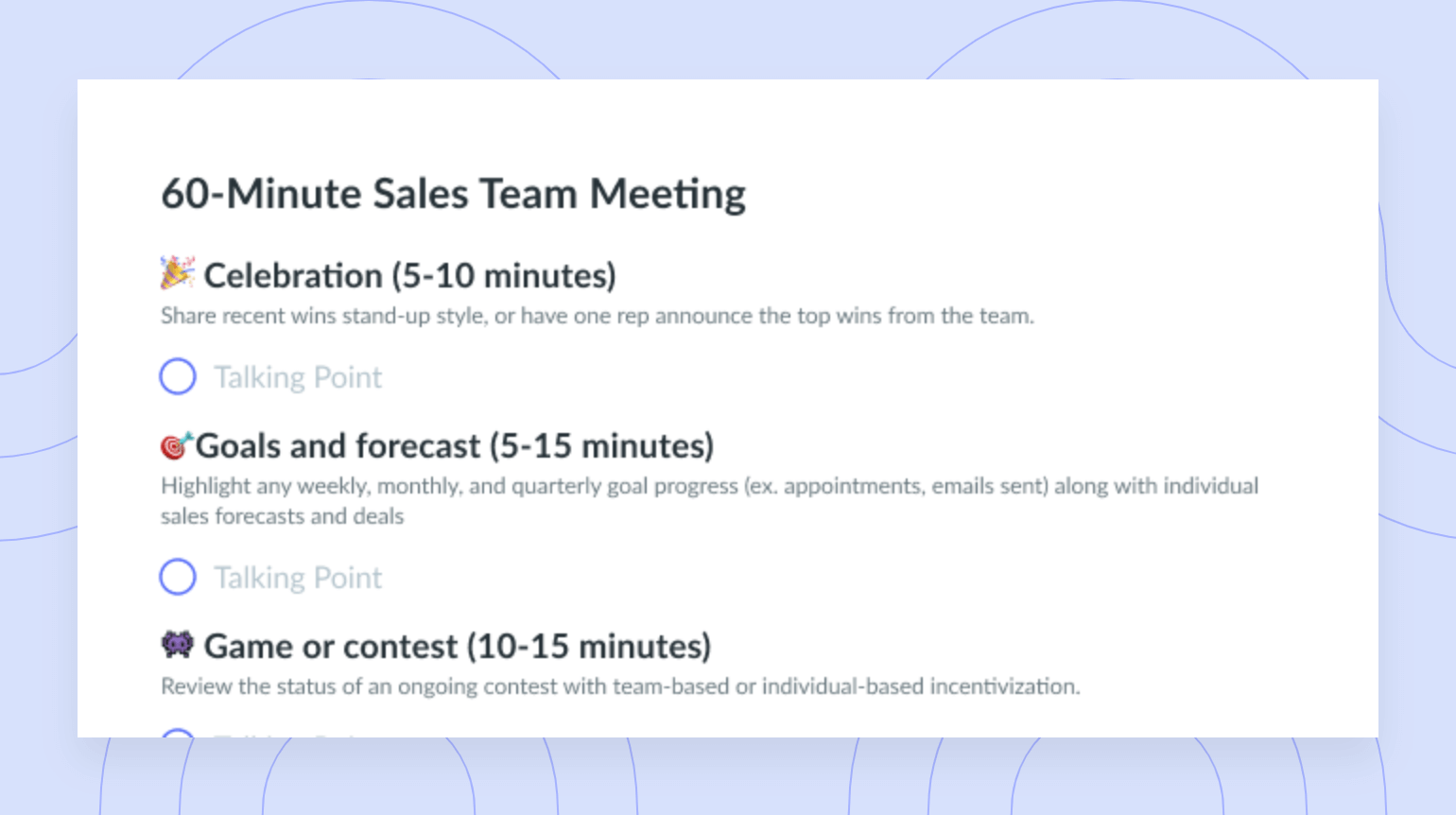

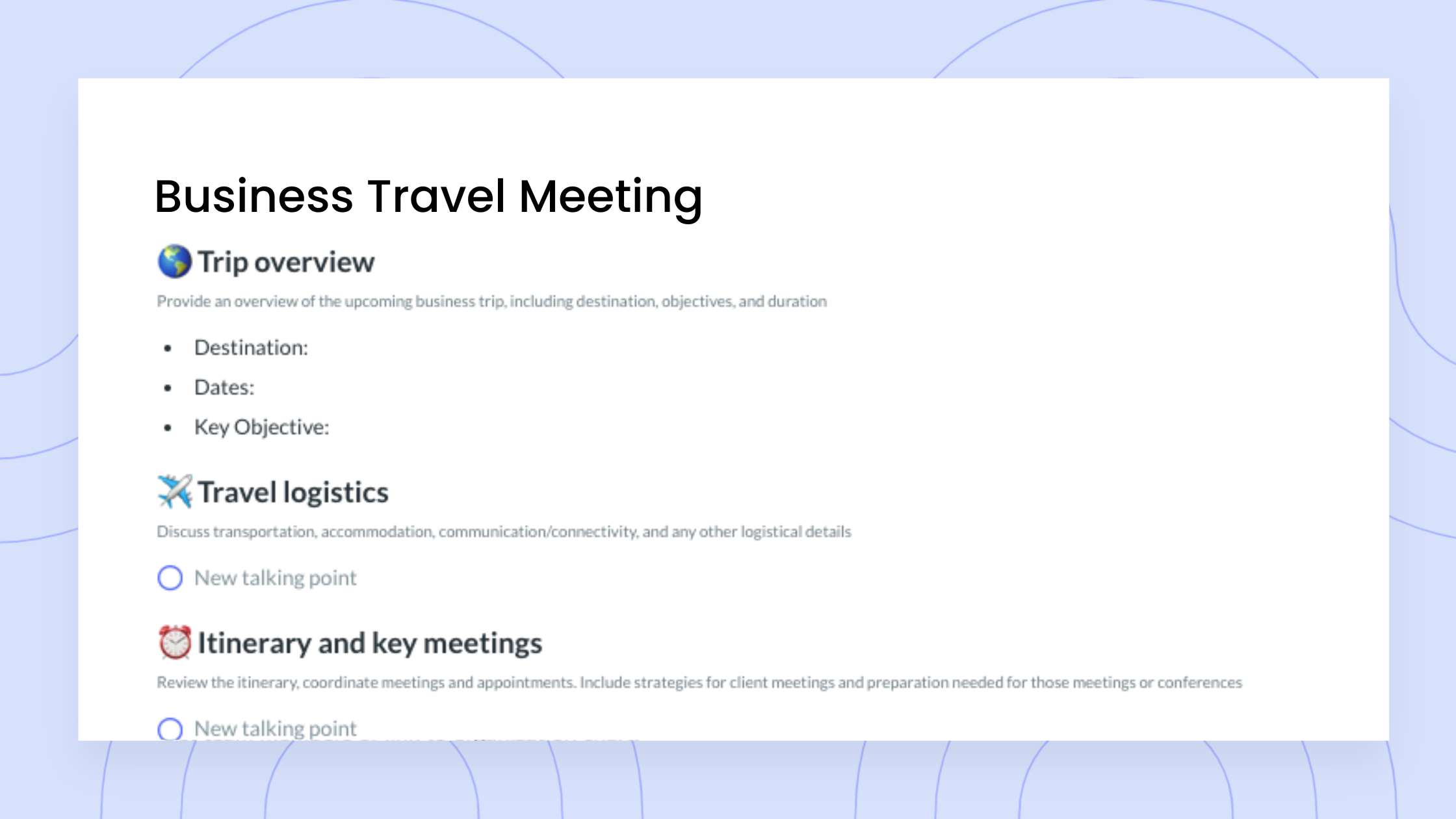

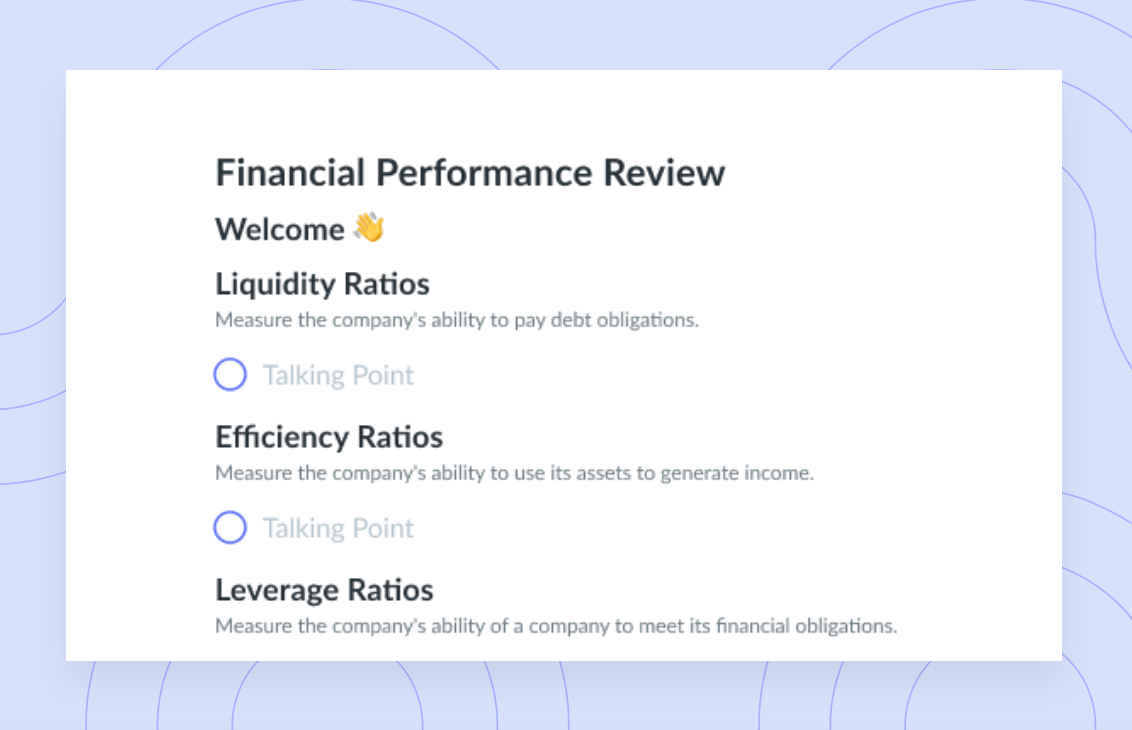

Continuously improving with Fellow

In Kaizen, you empower your whole team, and there’s no better place to do that than in meetings. There’s also no better way to inspire your team toward greatness than with clearly defined objectives. With Fellow, you’re fully equipped to accomplish both, with features like clear meeting agendas, meeting action items, AI meeting transcription, feedback tools, and OKR tools. Set and track goals, assign goal-oriented tasks during meetings, and get a full written record of your conversations afterward. Use Fellow to improve today, tomorrow, and onward!